Heat Exchanger vs Dual Boiler: Commercial Espresso Machine Guide

Heat Exchanger vs Dual Boiler: Commercial Espresso Machine Guide

Choosing the right boiler system is one of the most critical decisions when selecting commercial espresso equipment. The boiler configuration directly impacts brewing consistency, operational efficiency, and overall beverage quality. This comprehensive guide examines heat exchanger and dual boiler systems, helping coffee shop owners and operators make informed equipment decisions that align with their budget, operational needs and business goals.

Key Sections:

- Technical explanations of how each system works

- Detailed advantages and limitations for both technologies

- Performance comparison across temperature consistency, workflow, and quality

- Commercial applications with specific recommendations by operation type

- Cost analysis including initial investment, operating costs, and ROI considerations

- Selection criteria and decision framework for choosing the right system

- Best practices for optimizing each system type

Article Highlights:

- Explains temperature requirements for brewing vs steaming

- Provides specific cost ranges and energy consumption differences

- Offers volume-based recommendations (100, 200+ beverages daily)

- Includes practical operational tips for both system types

- Discusses future technology trends

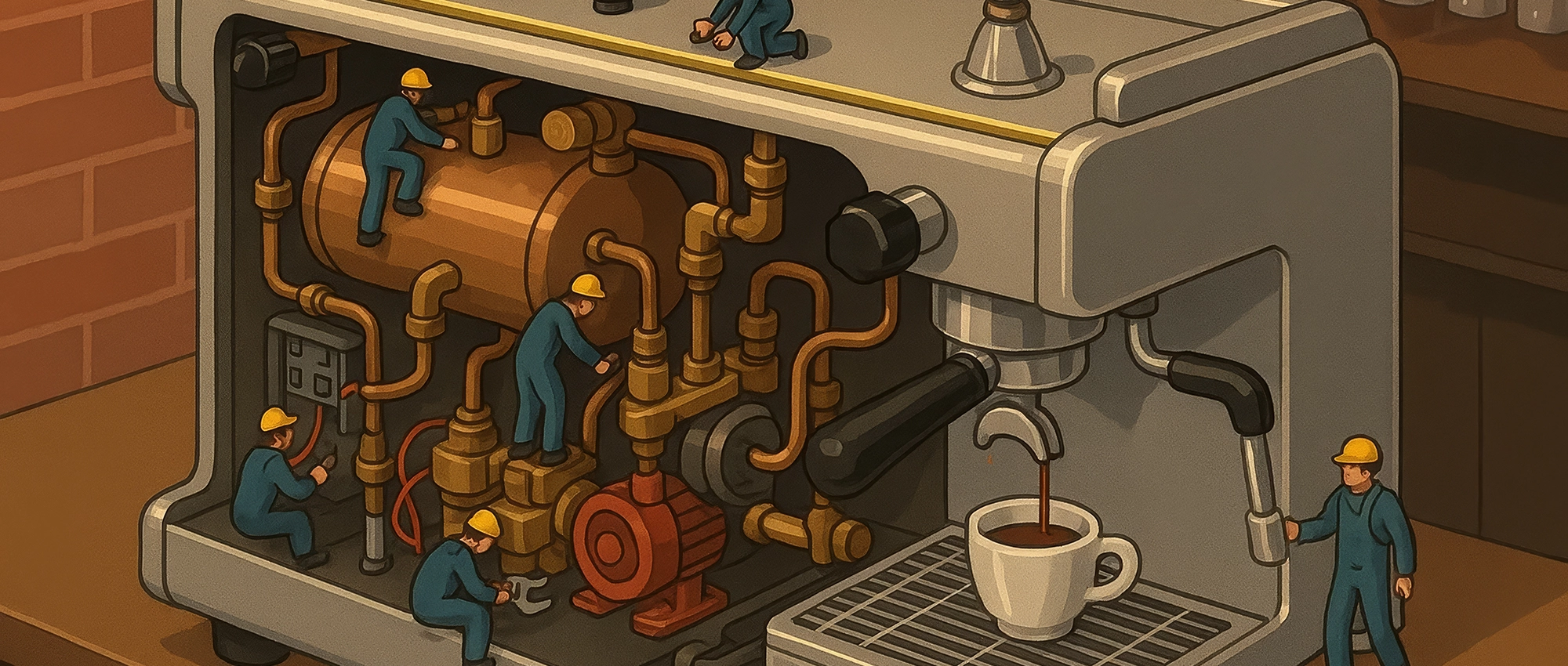

Understanding Espresso Machine Boiler Systems

The Role of Boilers in Espresso Machines

Commercial espresso machines require precise temperature control for two distinct functions: brewing espresso and producing steam for milk-based beverages. Brewing requires water temperatures between 190-196°F, while steam production needs temperatures around 250-260°F. The boiler system determines how effectively a machine manages these different temperature requirements.

Why Boiler Configuration Matters

The boiler system impacts several critical operational factors including temperature stability, simultaneous brewing and steaming capability, energy efficiency, and maintenance requirements. Understanding these differences helps operators choose equipment that maximizes productivity while maintaining consistent beverage quality.

Heat Exchanger Systems Explained

How Heat Exchanger Technology Works

Heat exchanger espresso machines use a single large boiler filled with water maintained at steam temperature (approximately 250°F). A heat exchange coil runs through this boiler, allowing fresh water to pass through and reach optimal brewing temperature as it travels to the group head. This design enables simultaneous brewing and steaming using one boiler system.

Heat Exchanger Advantages

Cost Effectiveness: Heat exchanger machines typically cost 20-40% less than comparable dual boiler systems, making them attractive for budget-conscious operations or startup coffee shops.

Simultaneous Operation: The system allows baristas to brew espresso while simultaneously steaming milk, improving workflow efficiency during busy periods.

Faster Heat-Up Time: Single boiler systems generally reach operating temperature more quickly than dual boiler configurations, reducing morning startup time.

Simpler Maintenance: Fewer boilers mean fewer components to maintain, potentially reducing service complexity and maintenance costs.

Space Efficiency: Heat exchanger systems often have more compact footprints, valuable in space-limited commercial spaces.

Heat Exchanger Limitations

Temperature Fluctuation: The heat exchange process can create temperature variations in brewing water, potentially affecting extraction consistency and espresso quality.

Thermal Management Challenges: During high-volume periods, continuous steam use can affect brewing water temperature, requiring careful operational timing.

Limited Temperature Control: Most heat exchanger systems offer minimal brewing temperature adjustment capabilities, reducing flexibility for different coffee profiles.

Recovery Time: Heavy steam usage can impact brewing temperature recovery, potentially creating quality inconsistencies during peak service.

Dual Boiler Systems Explained

How Dual Boiler Technology Works

Dual boiler espresso machines feature two separate boilers: one dedicated exclusively to brewing (typically 1-3 liters) and another for steam production (usually 5-20 liters). Each boiler maintains its optimal temperature independently, providing precise control over both brewing and steaming functions.

Dual Boiler Advantages

Superior Temperature Stability: Independent boilers ensure brewing water temperature remains consistent regardless of steam usage, delivering superior extraction consistency.

Precise Temperature Control: Many dual boiler systems offer programmable brewing temperatures, allowing operators to optimize extraction for different coffee profiles and seasonal variations.

High-Volume Performance: Independent systems handle continuous operation without temperature compromise, ideal for high-volume coffee shops and busy commercial environments.

Brewing Flexibility: Separate temperature controls enable operators to fine-tune brewing parameters for single-origin coffees, seasonal blends, and customer preferences.

Professional Quality: Dual boiler systems typically deliver the most consistent results, meeting the demands of specialty coffee operations focused on quality excellence.

Dual Boiler Limitations

Higher Initial Investment: Dual boiler machines typically cost 40-60% more than heat exchanger equivalents, requiring larger capital investments.

Increased Energy Consumption: Two boilers consume more electricity, resulting in higher operating costs and larger environmental footprints.

Complex Maintenance: Additional components and systems increase maintenance complexity and potential repair costs over time.

Longer Heat-Up Time: Two boilers require more time to reach operating temperature, extending morning startup procedures (generally 30-minutes).

Space Requirements: Dual boiler systems often have larger footprints, requiring more counter space and potentially limiting placement options.

Performance Comparison Analysis

Temperature Consistency

Dual boiler systems provide superior temperature consistency, with brewing water temperature variations typically within ±1°F. Heat exchanger systems may experience ±3-5°F variations depending on steam usage patterns and operational timing.

Workflow Efficiency

Both systems enable simultaneous brewing and steaming, but dual boiler systems maintain consistent performance regardless of usage patterns. Heat exchanger systems may require operational adjustments during high-volume periods to maintain quality standards.

Quality Potential

While skilled baristas can produce excellent espresso with both systems, dual boiler machines offer greater consistency and quality potential, particularly important for specialty coffee operations emphasizing extraction precision.

Operational Flexibility

Dual boiler systems provide significantly more operational flexibility through independent temperature controls and programming capabilities. Heat exchanger systems offer limited adjustment options, potentially restricting menu development and seasonal adaptations.

Commercial Applications and Recommendations

High-Volume Coffee Shops

Operations serving 200+ espresso-based beverages daily benefit significantly from dual boiler systems. The consistent temperature control and high-volume performance justify the additional investment through improved quality consistency and operational efficiency.

Medium-Volume Operations

Coffee shops serving 100-200 beverages daily can succeed with either system. The choice depends on quality priorities, budget constraints, and growth projections. Operations planning expansion should consider dual boiler investments for future scalability.

Startup and Budget-Conscious Operations

Heat exchanger systems provide excellent entry points for new coffee shops or budget-limited operations. The lower initial investment and simpler maintenance requirements make them attractive for businesses building customer bases and cash flow.

Specialty Coffee Focus

Operations emphasizing single-origin coffees, seasonal menu changes, or competition-level quality should prioritize dual boiler systems. The precise temperature control and consistency capabilities support the quality standards specialty coffee customers expect.

Cost Analysis and ROI Considerations

Initial Investment Comparison

Heat exchanger machines typically range from $3,000-8,000 for commercial-grade equipment, while comparable dual boiler systems cost $5,000-15,000. The price difference varies by manufacturer, features, and capacity.

Operating Cost Differences

Dual boiler systems consume approximately 20-30% more electricity due to additional heating elements. For typical commercial operations, this translates to $50-150 monthly additional energy costs.

Maintenance Cost Factors

Heat exchanger systems generally have lower maintenance costs due to simpler designs, while dual boiler systems may require more frequent service due to additional components. However, quality dual boiler machines often feature better build quality that can offset maintenance differences.

Revenue Impact Analysis

Dual boiler systems can improve revenue through faster service, higher quality consistency, and reduced waste from temperature-related quality issues. High-volume operations may recover the additional investment within 12-18 months through operational improvements.

Selection Criteria and Decision Framework

Volume Requirements

Operations consistently serving fewer than 100 beverages daily can achieve excellent results with quality heat exchanger systems. Higher volume operations benefit significantly from dual boiler investments.

Quality Standards

Businesses positioning themselves as specialty coffee destinations should prioritize dual boiler systems for the temperature control and consistency advantages they provide.

Budget Considerations

While dual boiler systems offer superior performance, heat exchanger machines can deliver excellent results when properly operated. Budget constraints shouldn’t prevent businesses from entering the specialty coffee market.

Growth Projections

Businesses planning rapid growth or expansion should consider dual boiler investments to avoid equipment replacement costs as volume increases.

Staff Training Requirements

Heat exchanger systems require more operational skill to maintain quality during busy periods, while dual boiler systems are more forgiving of operational variations.

Best Practices for Each System Type

Heat Exchanger Operation Tips

Implement temperature surfing techniques during busy periods, schedule steam-heavy drinks strategically, monitor brewing temperature consistency, and train staff on thermal management principles.

Dual Boiler Optimization

Utilize programmable temperature settings for different coffee profiles, implement regular calibration schedules, take advantage of independent system maintenance capabilities, and optimize energy consumption through programmable timers.

Future Technology Considerations

Smart Technology Integration

Both boiler types are increasingly available with IoT connectivity, remote monitoring capabilities, and automated maintenance alerts. These features can improve operational efficiency regardless of boiler configuration.

Energy Efficiency Improvements

Newer dual boiler systems incorporate energy-saving technologies that reduce the operational cost differences between boiler types, making dual boiler systems more attractive for environmentally conscious operations.

Conclusion

The choice between heat exchanger and dual boiler systems depends on operational priorities, quality standards, volume requirements, and budget considerations. Heat exchanger systems offer excellent value for medium-volume operations with budget constraints, while dual boiler systems provide superior consistency and performance for high-volume or quality-focused businesses.

Both technologies can produce exceptional espresso when properly operated and maintained. The key is selecting equipment that aligns with your operational needs, quality goals, and business growth plans. Consider your daily volume, quality standards, staff training capabilities, and long-term business objectives when making this critical equipment decision.

Successful coffee operations have thrived with both boiler types. The most important factors are choosing quality equipment from reputable manufacturers, implementing proper training programs, and maintaining consistent operational standards regardless of the technology selected. If you have questions about either of these technologies please don’t hesitate to contact us. We’ll answer your questions whether you purchase from us or not.

Gary Downey

Gary Downey

Tags :

Coffee U Sunday: Weekly Coffee Business Education

Get expert coffee insights delivered to your inbox every Sunday. Equipment guides, brewing tips, business strategies, and industry trends to help your business succeed.

Categories

Categories

- Coffee Brewers (1)

- Coffee Business Success (8)

- Coffee Grinders (1)

- Coffee Shop Owners (7)

- Coffee Technology (3)

- Cold Brew Coffee (2)

- Espresso Machines (8)

- Espresso Shots (3)

- La Marzocco (2)

- Maintenance & Service (2)

- Specialty Coffee Drinks (3)

- Water Treatment (1)

📚 Equipment Guides

Comprehensive breakdowns of different machine types, helping you make informed purchasing decisions

Maintenance Tips

Maintenance Tips

Professional techniques to keep your equipment running at peak performance and extend its lifespan

Brewing Science

Brewing Science

Understand the ‘why’ behind extraction, temperature stability, and equipment design

Troubleshooting Help

Troubleshooting Help

Common problems and solutions to minimize downtime and service calls

Business Insights

Business Insights

ROI calculations, workflow optimization, and equipment selection for your specific needs

Technology Explained

Technology Explained

Demystifying features like PID control, pressure profiling, and heat exchange systems

Coffee U Sunday: Weekly Coffee Business Education

Get expert coffee insights delivered to your inbox every Sunday. Equipment guides, brewing tips, business strategies, and industry trends to help your business succeed.

Share

Use our search function or browse by category to find exactly what you need. Can’t find an answer? Contact us directly, your question might inspire our next Coffee U article! As we grow, so will this resource, shaped by the real needs of coffee professionals like you.

Start exploring Coffee U today and discover why Bean & Brew Technologies is committed to elevating the coffee industry through education and exceptional service.

Have a question?

We're here to help.